FSCT820/650 SERIES Intelligence Pressure and Vacuum Multi-Station Thermoforming Machine

Major Construction Features:

1. European design, complete functions, suitable for diversified production lines, safe, efficient, energy-saving and hygienic

2. Unwinding station electric lifting, double roll holder. allow for single operator loading rolls up to 1T

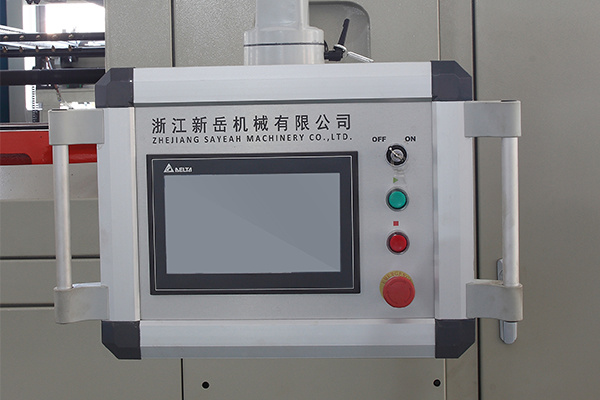

3. Operator-friendly HMI, and the system has the function of remote connection

4. Fast and accurate temperature control system (error ± 1 degree), with hot furnace detection material drop and air source low pressure protection system

5. Intelligent operation, the whole machine is equipped with formula storage and automatic adjustment without shutdown

6. It can share molds with models of most well-known brands at home and abroad, and cooperate with existing production lines

7. Fast mold change system, which can facilitate fast, accurate and safe mold change and reduce machine downtime

8. Under any forming scheme, the clamping frame and plug assist function can be used alone or at the same time, greatly simplify the mold structure

9. Materials with strong shrinkage can adopt the single station in-mold-forming-cutting function to 100% ensure the edge cutting accuracy

10. High precision forming and cutting technology to achieve the perfect forming and cutting performance of high-speed control and low wear

11. The stacking station can be customized, which simplifies the stacking of complex parts and is convenient to meet further production needs

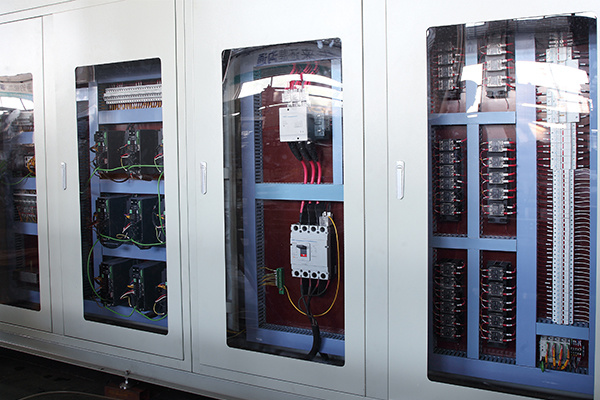

12. Optimize the design of electric cabinet and simplify the machine assembly and wiring installation process

Main Technical Parameters:

| Mode | FSCT820/650-2 | FSCT820/650-3 | FSCT820/650-4 |

| Qty of Stations | 2 | 3 | 4 |

| Sheet Material | PP,PS,PET,PVC,HIPS,PLA,OPS,EPS,C-PET,C-PLA,ABS | ||

| Forming Clamping Force | 750KN | ||

| Punching Clamping Force | 750KN | ||

| Max.Forming Area | 820x650mm | ||

| Max.Pos/Neg Depth | 150/150 | ||

| Max.Plastic Sheet Width | 860mm | ||

| Max.Sheet Roll Dia | 1100mm,1T | ||

| Sheet Thickness Range | 0.15-2mm | ||

| Max.No-Load Speed | 65 Cycles/min | ||

| Air Consumption | 4.5m³/min,0.6-0.8Mpa | ||

| Rated Power | 185KW | 200KW | 215KW |

| Dimension(LxWxH) | 10000×2900×3150mm | 11200x2900x3150mm | 12500x2900x3150mm |

| Weight | 15T | 20T | 25T |

Notes: If any change of data, we will not notify further

|

|

|

|

Sheet Loading and Feeding station: driving by motor. sheet roll Max diameter 1M. with dust-free plate to keep the sheet clean. |

Touch Screen: The operation of the machine is controlled by the PLC Touch Screen. The whole machine has the function of formula storage and electric adjustment. This function reduces the workload for the operator and the requirements of the technique. |

|

|

|

Preheater: Has the In-feed sheet edge pre-heater system before the sheet goes into the heater part, it reduces the defective percentage, keep dust-free environment to improve the quality of the product and prolong the life of conveying chain . |

The plastic sheet was sent by the sharp tooth, which was driven by the servo-motor. The width of the Chain can be adjusted and wear cooling water, which can prolong the life of the chain and reduce the dust. |

|

|

|

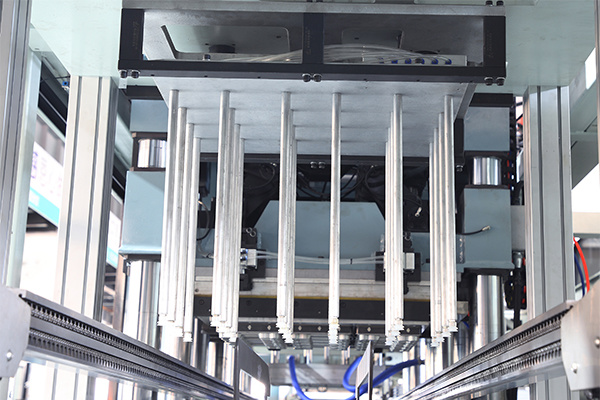

Ceramic heater: Temperature is controlled precisely (the difference is within ±1℃). The working life of the ceramic heater is long and adopts the fully enclosed oven. The temperature controlling system is better and saves more energy. |

Electric cabinet: The connection of the electric cabinet is easy. Equipping the air conditioner to prolong the life of the electric parts. |

|

|

|

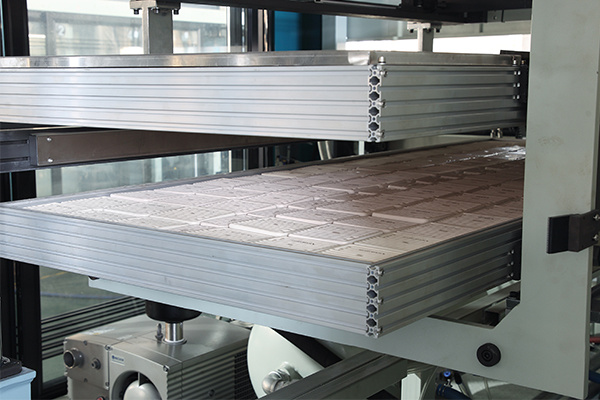

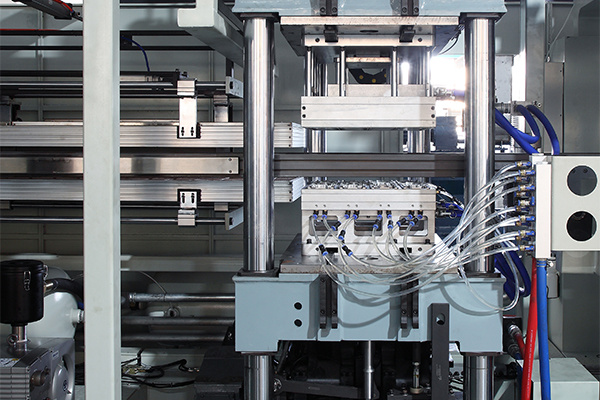

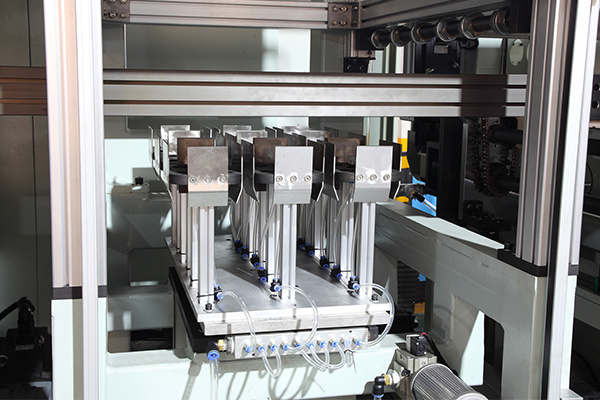

The forming station is driven by servo motor to close the mold, with cylinder clamping frame and servo stretching function at the same time. |

The vacuum pump is from German BECKER to meet all kinds of requirements for different products. In addition, it also has automatic lubricator pump to prolong the life of the machine. |

|

|

|

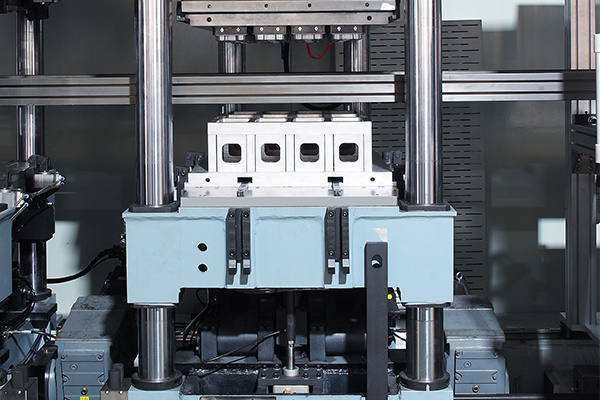

The punching station has an automatic mold fixing system, which can be fixed after the installation and adjustment. Don’t need screws to fix the mold and can short the setting time of the mold. It can improve efficiency. And the cutter has heat functions. |

Stacking station:Stacking station has many options to design that can meet more demands of packing. |

|

|

| The installation of the mold is easy and safe, it can short the setting time of the mold. Using the mold change bracket can improve the efficiency of changing mold, it has a double safety bolt to ensure safety. | Mold |

рекомендовать модель