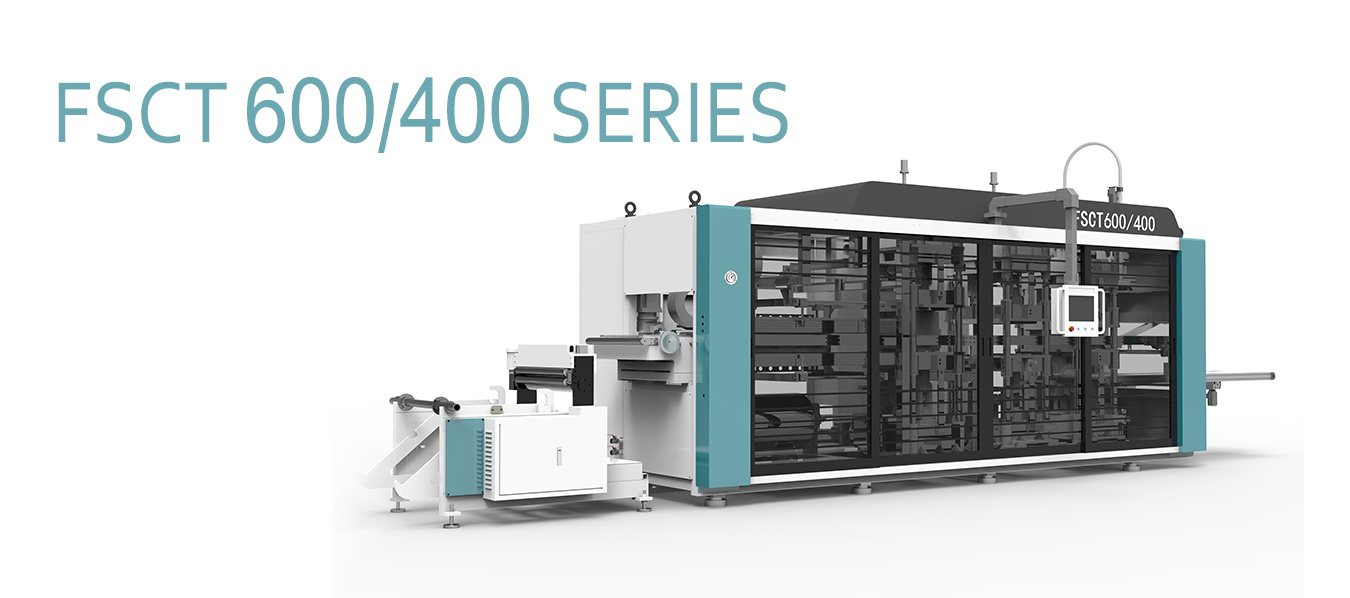

FSCT600/400 SERIES Fully Automatic Pressure Multi-Station Thermoforming Machine

Major Construction Features:

1. European design, suitable for diversified production lines, safe, efficient, energy-saving and hygienic

2. Compact structure, stable and efficient operation, easy for daily operation and maintenance

3. Unwinding station electric lifting, double roll holder. allow for single operator loading rolls up to 1T

4. Fast and accurate temperature control system (error ± 1 degree), which can reach the set temperature in ten minutes

5. Various materials can be used, which is suitable for all kinds of small and medium-sized batch orders

6. Quick front mold change, safe and simple die change, reducing machine downtime

7. Materials with strong shrinkage can adopt the single station die forming and punching function to 100% ensure the die edge cutting accuracy

8. High cost performance, low failure rate, abnormal alarm response mode, reducing the time cost of troubleshooting

9. Remote maintenance, instant judgment of obstacle messages, rapid correction and repair of problems

10. Integrated design of electric cabinet to simplify machine assembly and wiring installation process

Main Technical Parameters:

| Mode | FSCT600/400-2 | FSCT600/400-3 | FSCT600/400-4 |

| Qty of Stations | 2 | 3 | 4 |

| Max.Forming Area | 600×400mm | ||

| Max.Forming Depth | 80/40mm | ||

| Max.Sheet Width | 640mm | ||

| Max.Sheet Roll Dia. | 1100mm,1T | ||

| Sheet Thickness Range | 0.15-2mm | ||

| Max.Dry Cycle Speed | 35 Cycles/min | ||

| Overall Power | 85KW | 90KW | 95KW |

| Dimension(L×W×H) | 7600×2100×3200mm | 8200×2100×3200mm | 9000×2100×3200mm |

| Machine Weight | 4T | 5.5T | 7T |

Notes: If any change of data, we will not notify further

|

|

|

|

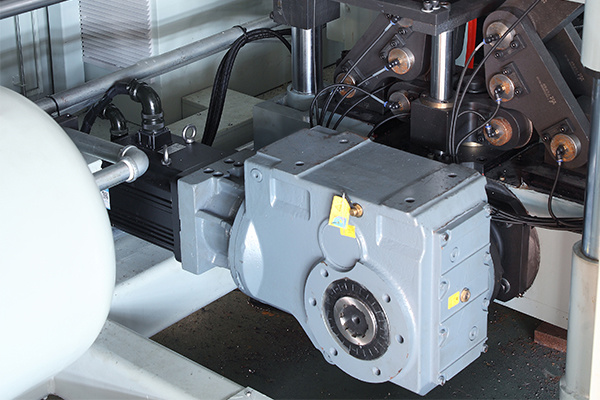

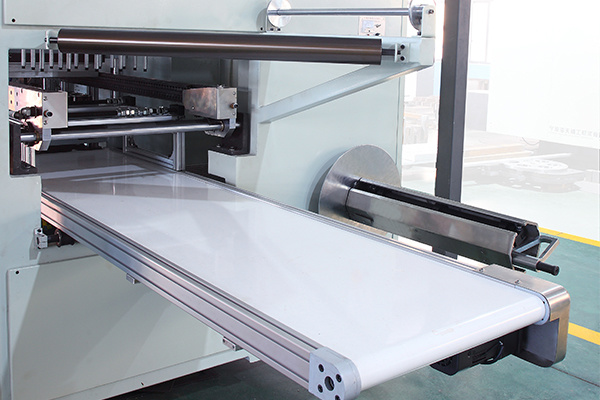

Sheet Loading and Feeding station: driving by motor. sheet roll Max diameter 1M. with dust-free plate to keep the sheet clean. |

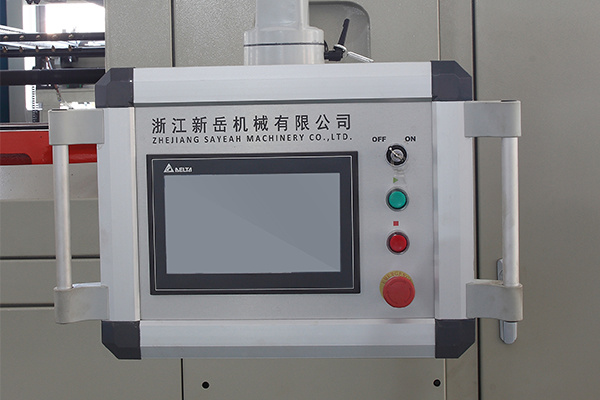

The touch screen is easy to operate, all-electric adjustments can be done on the touch screen. |

|

|

|

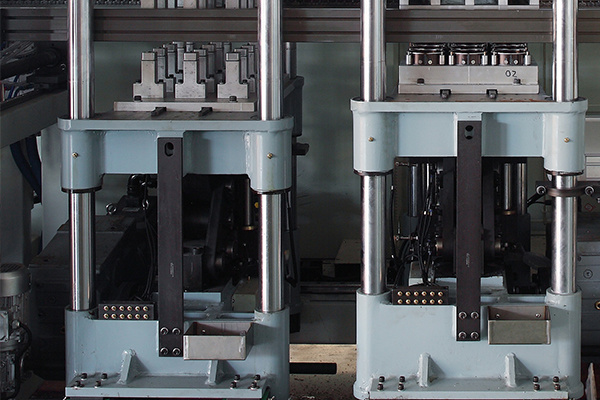

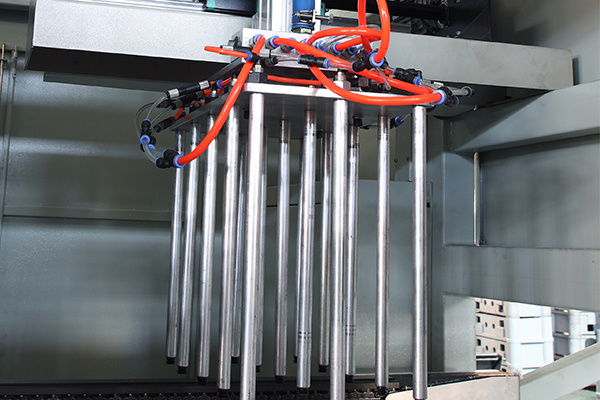

The upper and lower mold guides can move up and down to produce various convex and concave products to meet various production needs. |

Quick front mold change, safe and simple die change, reducing machine downtime |

|

|

| Various materials can be used, such as PP, PS, PET, PVC, etc., as well as environmental friendly material PLA。 |

The machine is equipped with automatic waste edge winding device, which is reasonable in layout, solid and durable. |

рекомендовать модель